What is Voice Picking?

Dematic’s voice picking warehouse solutions deliver considerable benefits in terms of productivity, accuracy and flexibility for new operations and those looking to modernise and upgrade.

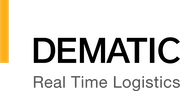

Voice Technology is now recognised as one of the most effective methods for increasing the productivity, accuracy and safety of many distribution centre operations.

Voice picking solutions use innovative technology and software that directs warehouse operators to certain storage locations and tells them what to pick and where to put it.

How does it work? By wearing a headset designed for comfort, a picker listens to the instructions and confirms locations and quantities etc. by simply speaking back to the system. Voice recognition software understands the response – even in a noisy warehouse – and then continues to direct the picker accordingly.

The benefits of Voice Picking Systems don’t stop in the warehouse. Dematic provides its customers with Voice solutions from our partner Honeywell, designed and optimised for end-to-end supply chain applications, whether in a warehouse, port, yard or factory.

Dematic is very proud to be a Honeywell Platinum Level partner (previously Vocollect) and Total Solution Provider in Australia and New Zealand, providing quality Honeywell Voice-centric solutions.

Check out some of Honeywell’s newest voice devices below. If you would like more information about a Voice solution that is tailored to your requirements,

Download Voice Directed Warehouse BrochureVoice Products

Voice picking solutions

with Real Time Logistics

Voice picking solutions use innovative technology and software that directs warehouse operators to certain storage locations and tells them what to pick and where to put it.

Wearing a headset designed for comfort, a picker listens to the instructions and confirms locations and quantities etc. by simply speaking back to the system. Warehouse Voice picking systems understands the response through state-of-the-art voice recognition technology – even in a noisy warehouse – and then continues to direct the picker accordingly. Pick to voice systems are the future of warehousing.

Benefits of voice-directed warehousing

The major benefit of voice recognition technology is that the manual picking process is made easier. Locations are fast and easy to identify, quantities are confirmed with the system and voice pickers can work continuously without the need to look down to find his or her place on a long picklist. With enhanced speech recognition software, picking issues are reduced, picks are completed more quickly, and any discrepancies between the data and the inventory are sorted out as you go.

With voice instruction, the terminal prompts the operator through each picking assignment. To verify the correct location and product being picked, pickers read the location’s assigned check digit or the last three digits of the product barcode. The voice implementation system verifies this and then tells the picker with the quantity to pick.

Dematic’s voice picking solutions – now on Android!

Voice warehousing is now available to businesses using devices running on the Android™ operating system.

Automated Voice Solutions made easy

Operators wear a portable, belt-mounted voice terminal and a wireless headset. Workers are able to hear instructions and perform tasks without having to look down at a hand-held computer screen or sort through paper lists. Voice picking is hands and eyes-free, allowing staff to work more safely, efficiently and accurately.

The voice terminal communicates wirelessly in real-time with the host computer or Warehouse Management System (WMS), prompting the operator through each assignment, with verbal instructions. The operator verbally confirms the correct task has been executed via the headset microphone. The voice system verifies this and then gives the operator the next task.

Simple & effective 3rd party terminals

- Each picker trains the system to understand her voice in a once-only session that takes around 20 minutes.

- Training time is cut by up to 50% over other picking methods. Voice operators can be productive in a matter of hours and reach maximum productivity faster than with alternative technologies.

- Voice is available on dedicated voice terminals which provide the highest levels of recognition performance and robustness of operation.

- Alternatively, voice-enabled screen terminals can deliver the benefits of voice, thereby providing the highest levels of functionality and flexibility.

- Voice technology alone has significant benefits, but its capabilities are fully realised when it is seamlessly integrated with leading pick-to-conveyor, zone routing systems, and Pick Carts.

With verbal instructions, the voice terminal prompts the operator through each picking assignment. To verify the correct location and product being picked, pickers read the location’s assigned check digit or the last three digits of the product barcode. The voice system verifies this and then tells the picker with the quantity to pick.

Voice directed warehousing FAQ

What are the accuracy improvements I can expect from voice picking?

A voice picking operation can expect an error rate of 0.2 to two errors per 1000 picks (translating to 99.8 – 99.98% accuracy). PTL operations, on the other hand, make about three to five errors per 1000 picks (translating to 99.5 – 99.7% accuracy).

What productivity gains can I expect when using voice picking?

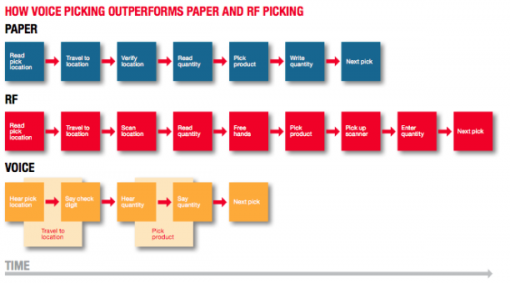

Companies that treat voice as a technology upgrade alone tend to see 5-10 per cent productivity gains, while companies that treat voice as part of a broader warehouse operations optimisation initiative see gains ranging from 25-35 per cent in case picking productivity, and 45 per cent or more in piece picking.

Does voice picking work in a noisy environment?

Yes, provided you use voice terminals specifically designed for noisy warehouses and industrial environments. Please contact a member of our team to discuss your options.

What is the major benefit of voice-directed warehousing?

Voice-directed warehousing allows employees to communicate verbally with computerised systems, rather than relying on other interfaces. Wearing headsets and exchanging spoken words with the computer is easy and intuitive, and allows employees’ hands and eyes to remain free for other tasks.

Can I re-label warehouse products?

Many times warehouse locations and products will need to be relabelled for the new system. Voice solutions prompt a worker to read back a set of check digits for the specific location. The time and money spent on prep need to be considered when implementing voice picking technology.

What about app design & voice recognition software?

Will the new application handle all exceptions or will there be types of transactions that allow, or require, the picker to go off the voice system? Dematic’s Voice specialists will work with your business to identify all the transactions and conditions you require.

Can I train existing staff on this new picking system?

Voice picking technology establishes a new system process and standard. Whilst this represents a big change in procedures for staff, in most cases, employee engagement is positive. Voice is easy to learn and workers using it can be productive within an hour, which is also helpful later on when bringing in new or temporary staff. When compared to the time it takes to learn other technology solutions, training time and costs can be cut dramatically with Voice, in many cases more than 50%.

Is there sufficient IT support?

Once the warehouse is on voice, any system and technology issues will need to be managed by experts. Dematic’s customer service team can provide you with a customised service plan to suit your requirements, including 24/7 support.